Kina OEM maʻamau spheroidal graphite hoolei hao pūpū mold hoolei huahana me nā lawelawe oʻO ka mīkini CNC, lapaʻau wela a mālama ʻili.

Ka hoʻoheheʻe ʻia ʻana o ka pūpūUa kapa ʻia ke kaʻina hana hoʻoheheʻe ʻana i ke one resin pre-coated, nā hoʻoheheʻe ʻana i ka pūpū wela a i ʻole ke kaʻina hoʻolei kumu. ʻO ka mea hoʻoheheʻe nui ka one phenolic resin pre-coated, ʻoi aku ka maikaʻi ma mua o ke one ʻōmaʻomaʻo a me ke one furan resin. Eia kekahi, ʻaʻole hiki ke hoʻohana hou ʻia kēia one.

ʻO ke kaʻina hoʻolei one paʻakikī paʻakikī Furan resin (nobake process) hoʻohana i ke one i uhi ʻia i ka furan resin e hana i ka mold. Ma hope o ka hui ʻana i ke one kumu (a i ʻole ke one i hoʻihoʻi ʻia), ka wai furan resin a me ka catalyst wai me ka like, a hoʻopiha iā lākou i loko o ka pahu kumu (a i ʻole pahu one), a laila e hoʻopaʻa i ka paʻakikī i loko o kahi ʻōpala a i ʻole i loko o ka pahu kumu (a i ʻole ke one. pahu) ma ka lumi wela. A laila ua hoʻokumu ʻia ka pahu hoʻoheheʻe a i ʻole ka hoʻoheheʻe ʻana i ke kumu, i kapa ʻia ʻo ia hoʻi ka paʻakikī paʻakikī paʻakikī pahu pahu (core), a i ʻole ke ʻano hana paʻakikī (core).

No ka mea, ua hoʻokumu ʻia ka mold i ka lumi wela a ʻaʻole pono e wela, ua kapa ʻia ka hoʻolei ʻana i ke one paʻakikī ponoʻī. Hiki ke hoʻokaʻawale ʻia ke ʻano paʻakikī paʻakikī i loko o ka acid-catalyzed furan resin a me ka phenolic resin sand self-hardening method, urethane resin sand self-hardening method and phenolic monoester self-hardening method.

Ma ke ʻano he one hoʻopaʻa pahu pahu anu paʻakikī ponoʻī, ʻo ke one furan resin ka mea mua loa a i kēia manawa i hoʻohana nui ʻia i ke one synthetic binder i loko o ka hale kūkulu Kina. ʻO ka nui o ka resin i hoʻohui ʻia i ke one hoʻoheheʻe ʻia ma ke ʻano he 0.7% a 1.0%, a ʻo ka nui o ka resin i hoʻohui ʻia i ke one kumu maʻamau he 0.9% a 1.1%. ʻO ka maʻiʻo o ka aldehyde manuahi i ka resin furan aia ma lalo o 0.3%, a ua hāʻule kekahi mau hale hana ma lalo o 0.1%. I loko o nā hale kūʻai ma Kina, ua hōʻea ke one paʻakikī paʻakikī furan resin i ka pae honua me ka nānā ʻole i ke kaʻina hana a me ka maikaʻi o ka ʻili o nā castings.

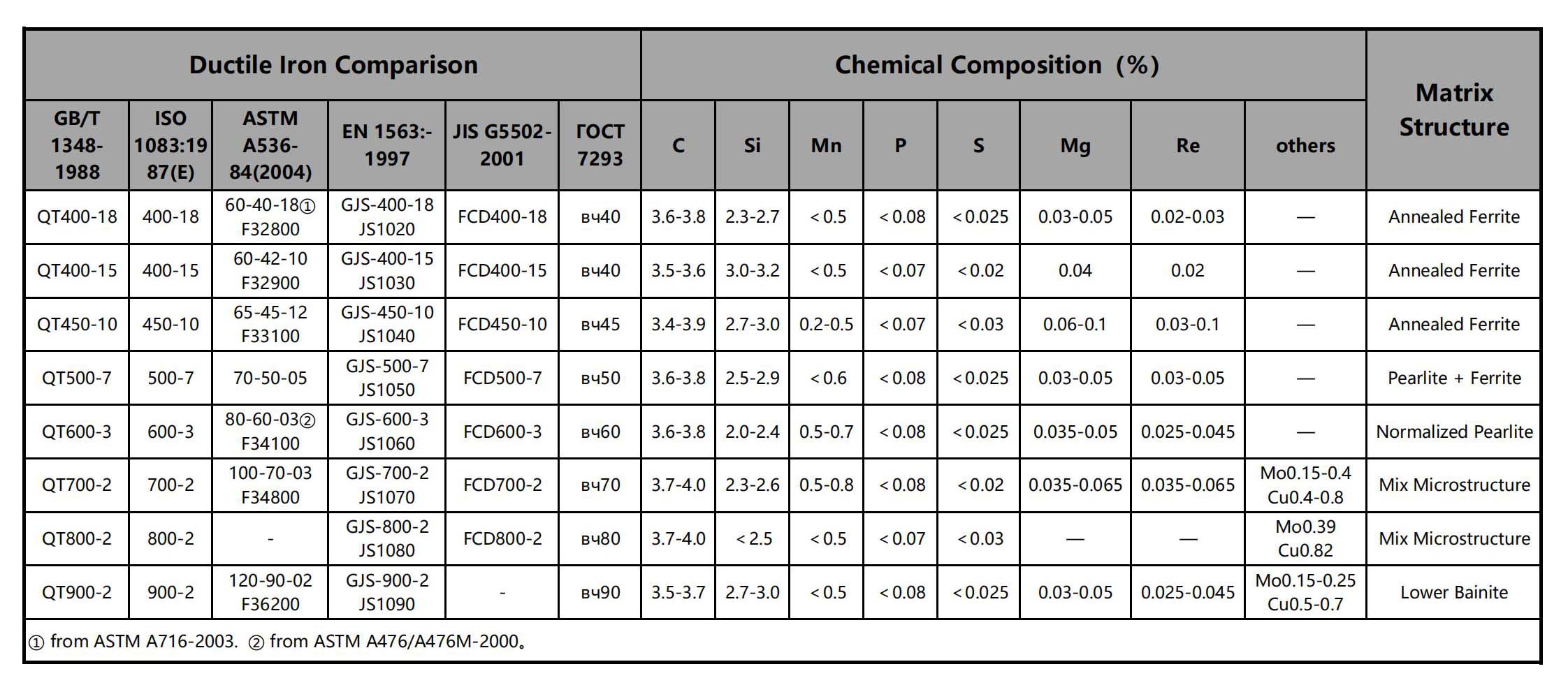

ʻO ka hao hoʻoheheʻe ʻia, ʻo ia hoʻi ka mea i kapa ʻia ʻo nodular cast iron, spheriodal graphite cast iron a i ʻole SG hao wale no ka pōkole, e hōʻike ana i kahi hui o ka hao. Loaʻa ka hao nodular i ka graphite nodular ma o ka spheroidization a me ka mālama inoculation, kahi e hoʻomaikaʻi maikaʻi ai i nā waiwai mechanical o ka hao, ʻoi aku ka paʻakikī a me ka paʻakikī, i loaʻa ai ka ikaika kiʻekiʻe ma mua o ke kila kalapona.

ʻOi aku ka maikaʻi o ka hoʻoheheʻe ʻana i ka hao ma mua o ke kila kalapona, ʻoiai ʻoi aku ka maikaʻi o ka weldability o ka hoʻoheheʻe ʻana. A i kekahi manawa, hiki i ka ductile iorn castings ke loaʻa i kekahi mau hana o ka pale ʻana i ka lole a me ka ʻōpala. No laila hiki ke hoʻohana ʻia ka hoʻolei hao ductile no kekahi mau hale pahū a i ʻole nā pūnaewele wai. Eia nō naʻe, pono mākou e mālama i ka pale ʻana iā lākou mai ka ʻaʻahu a me ka ʻōpala.

ʻAʻole ʻo Ductile iron he mea hoʻokahi akā he ʻāpana ia o ka pūʻulu o nā mea hiki ke hana ʻia e loaʻa i kahi ākea ākea ma o ka mālama ʻana i ka microstructure. ʻO ka hiʻohiʻona maʻamau o kēia pūʻulu mea ʻo ke ʻano o ka graphite. I loko o nā hao ductile, aia ka graphite ma ke ʻano o nā nodules ma mua o nā flakes e like me ka hao hina. ʻO ke ʻano ʻoi o nā flakes o ka graphite e hoʻokumu i nā wahi koʻikoʻi koʻikoʻi i loko o ka matrix metala a me ke ʻano poepoe o nā nodules ʻoi aku ka liʻiliʻi, pēlā e pale ai i ka hana ʻana o nā māwae a hāʻawi i ka ductility i hoʻonui ʻia e hāʻawi i ka inoa i ka alloy. No laila, ma ka ʻōlelo maʻamau, inā hiki i ka hao ductile ke hoʻokō i kāu mau koi, ʻo ka hao ductile paha kāu koho mua, ma kahi o ke kila kalapona no kāu hoʻolei ʻana.

| ʻO ke one hoʻoheheʻe resina me nā mea hoʻohui | |

| Metala & Alloys | Papa kaulana |

| Hao Hao Hina | GG10~GG40; GJL-100 ~ GJL-350; |

| Ka hao hoolei (Nodular). | GGG40 ~ GGG80; GJS-400-18, GJS-40-15, GJS-450-10, GJS-500-7, GJS-600-3, GJS-700-2, GJS-800-2 |

| Austempered Ductile Iron (ADI) | EN-GJS-800-8, EN-GJS-1000-5, EN-GJS-1200-2 |

| ʻO ka hao hao | C20, C25, C30, C45 |

| ʻAiʻa kila | 20Mn, 45Mn, ZG20Cr, 40Cr, 20Mn5, 16CrMo4, 42CrMo, 40CrV, 20CrNiMo, GCr15, 9Mn2V |

| Kila kohu ʻole | ʻIle ʻoleʻa Ferritic, ʻIle Kūleʻa ʻole Martensitic, ʻIle Kūleʻa Austenitic, ʻIle Kūleʻa Paʻa ka ua |

| Aluminum Alloys | ASTM A356, ASTM A413, ASTM A360 |

| Ke keleawe / Copper-based Alloys | C21000, C23000, C27000, C34500, C37710, C86500, C87600, C87400, C87800, C52100, C51100 |

| Kūlana: ASTM, SAE, AISI, GOST, DIN, EN, ISO, a me GB | |

ʻO nā pono o ka Furan Resin Coated Sand Self-hardening Molding Casting:

1) E hoʻomaikaʻi i ka pololei o ka nui o nā castings a me ka ʻili o ka ʻili.

2) ʻAʻole pono ka hoʻomaloʻo ʻana o ke one (core) paʻakikī, hiki ke hoʻopakele i ka ikehu, a hiki ke hoʻohana ʻia nā pahu lāʻau a i ʻole nā pahu a me nā mamana.

3) He mea maʻalahi ka hoʻopili ʻana a me ka hāʻule ʻana o ke one paʻakikī ponoʻī, maʻalahi e hoʻomaʻemaʻe i ka hoʻolei ʻana, a hiki ke hoʻohana hou ʻia ke one kahiko, kahi e hoʻemi nui ai i ka ikaika o ka hana ʻana, hoʻohālike, hāʻule ke one, hoʻomaʻemaʻe a me nā loulou ʻē aʻe, a maʻalahi ka hoʻomaopopo ʻana i ka mechanization a i ʻole automation.

4) ʻO ka hapa nui o ka resin ma ke one he 0.8% ~ 2.0% wale nō, a he haʻahaʻa ke kumukūʻai piha o nā mea maka.

No ka mea he nui nā pono kū hoʻokahi i ʻōlelo ʻia ma luna, ʻaʻole hoʻohana ʻia ke ʻano paʻakikī ponoʻī no ka hana kumu, akā hoʻohana ʻia no ka hoʻoheheʻe ʻana. He mea kūpono ia no ka ʻāpana hoʻokahi a me ka hana liʻiliʻi liʻiliʻi, a hiki ke hana i ka hao hao, ke kila a me ka hoʻoheheʻe ʻole ʻia. Ua hoʻololi loa kekahi mau hale kūʻai ʻo Kina i nā lepo lepo maloʻo, nā lepo lepo sima, a me nā ʻāpana one aniani wai.

Na Huahana Hao Hoolei