ʻO ka ʻenehana electrocoating kahi lapaʻau i hoʻohana nui ʻia no ka pale ʻana i kahoolei metalaa me nā huahana machining CNC mai ka corrosion me ka hoʻopau maikaʻi. Nui nā mea kūʻai aku e nīnau i nā nīnau e pili ana i ka hoʻomaʻamaʻa ʻana i ka ʻili o nā hoʻoheheʻe metala aʻāpana mīkini pololei. E nānā kēia ʻatikala i ke kaʻina hana electrophoretic coating. Manaʻolana e kōkua ia i nā hoa a pau.

ʻO ka Electrocoating kahi ʻano uhi kahi e hoʻokaʻawale ʻia ai nā ʻāpana e like me nā puaʻa a me nā resins i hoʻokuʻu ʻia i ka hopena electrophoretic e neʻe a waiho ma ka ʻili o kekahi o nā electrodes me ka hoʻohana ʻana i kahi kahua uila waho. Ua hoʻokumuʻia ke kumumanaʻo o ka electrophoretic coating i ka hopena o nā makahiki 1930, akā ua hoʻomohalaʻia kēiaʻenehana a loaʻa i ka noiʻoihanaʻoihana ma hope o 1963. ʻO ka electrophoretic coating ka hana hana kūpono loa no nā uhi wai. Loaʻa i ka electrophoretic coating nā hiʻohiʻona o ka solubility wai, non-toxicity, a me ka mana maʻalahi. No ka mea he kūpono ia no ka mālama ʻana i nā mea hana conductive (metala castings, machined parts, forgings, sheet metal parts and welding parts, etc.), ua hoʻohana nui ʻia ke kaʻina hana electrophoretic i nā ʻoihana e like me nā kaʻa, nā mea hale, nā lako. , a me na lako hale.

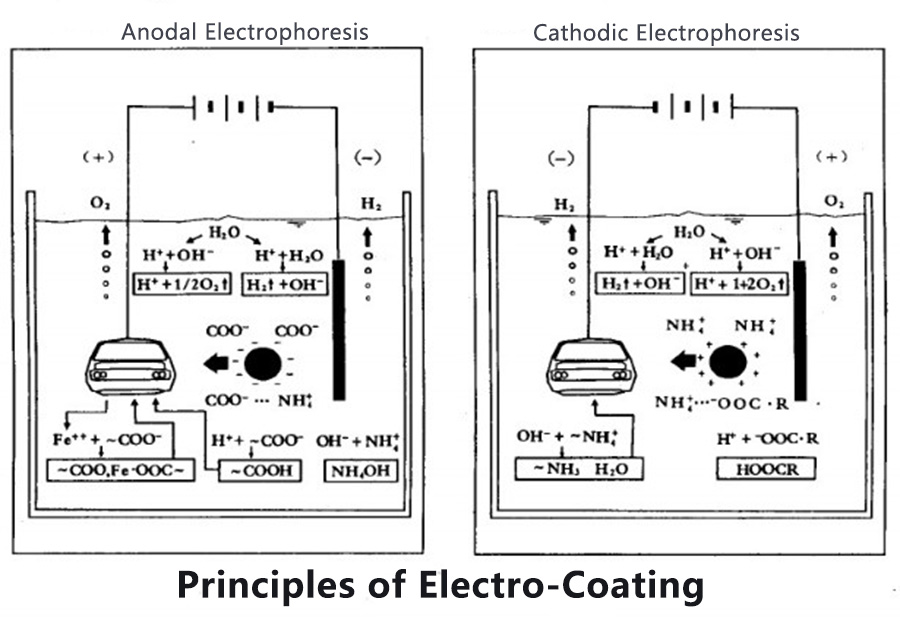

Nā loina

ʻO ka resin i loko o ka cathodic electrophoretic coating he mau pūʻulu maʻamau, e hana ana i ka paʻakai ma hope o ka neutralization acid a hoʻoheheʻe i ka wai. Ma hope o ka hoʻohana ʻia ʻana o ke au pololei, neʻe nā ionona ʻino radical acid i ka anode, a neʻe nā ion resin a me nā ʻāpana puaʻa i kāʻei ʻia e lākou i ka cathode me nā uku kūpono a waiho ʻia ma ka cathode. ʻO kēia ke kumu kumu o ka uhi electrophoretic (i ʻike ʻia ʻo plating). ʻO ka uhi ʻana o ka Electrophoresis he hopena electrochemical paʻakikī, ʻehā mau hopena o ka electrophoresis, electrodeposition, electrolysis, a me electroosmosis i ka manawa like.

Electrophoresis

Ma hope o ka hoʻoulu ʻia ʻana o ka anode a me ka cathode i ka hopena colloidal, neʻe nā ʻāpana colloidal i ka ʻaoʻao cathode (a i ʻole anode) ma lalo o ka hana o ke kahua uila, i kapa ʻia ʻo electrophoresis. ʻAʻole i loko o ke ʻano o nā molekala a me nā ion ka mea i loko o ka solution colloidal, akā ua hoʻopuehu ka solute i ka wai. Nui ka waiwai a ʻaʻole e hoʻoheheʻe ʻia i loko o kahi mokuʻāina.

Electrodeposition

ʻO ke ʻano o ka ua paʻa mai ka wai i kapa ʻia ʻo ka agglomeration (agglomeration, deposition), ka mea maʻamau i hana ʻia i ka wā e hoʻoluʻu a hoʻopaʻa ʻia i ka hopena, a hilinaʻi ka uhi electrophoretic i ka uila. I loko o ka cathodic electrophoretic coating, hoʻohui ʻia nā ʻāpana i hoʻopiʻi maikaʻi ʻia ma ka cathode, a ʻo nā mea i hoʻoili ʻole ʻia (ʻo ia hoʻi nā ion) i hui ʻia ma ka anode. I ka wā e hiki ai nā ʻāpana colloidal i hoʻopiʻi maikaʻi ʻia (resin a me ka puaʻa) i ka cathode (substrate) Ma hope o ka ʻāpana o ka ʻili (ka papa waena alkaline kiʻekiʻe), loaʻa nā electrons a hana ʻia me nā ion hydroxide e lilo i mau mea hiki ʻole i ka wai, i waiho ʻia ma ka cathode ( mea hana pena).

Electrolysis

I loko o kahi hoʻonā me ka ionic conductivity, pili ka anode a me ka cathode i ke au pololei, huki ʻia nā anion i ka anode, a huki ʻia nā cations i ka cathode, a loaʻa kahi hopena kemika. Hoʻopuka ka anode i ka hoʻoheheʻe metala a me ka electrolytic oxidation e hana i ka oxygen, chlorine, a me nā mea ʻē aʻe. Hoʻokahe ʻia ka metala ma ka cathode a hoʻemi ʻia ka H+ i ka hydrogen.

Electroosmosis

Ma hope o nā hopena ʻelua (cathode a me anode) o nā hāʻina me nā ʻokoʻa like ʻole i hoʻokaʻawale ʻia e kahi membrane semipermeable e hoʻoikaika ʻia, ʻo ke ʻano o ka neʻe ʻana o ka haʻahaʻa haʻahaʻa i ka ʻaoʻao kiʻekiʻe i kapa ʻia ʻo electroosmosis. ʻO ke kiʻi ʻoniʻoni i waiho wale ʻia ma ka ʻili o ka mea i uhi ʻia he kiʻi semi-permeable. Ma lalo o ka hana mau o ke kahua uila, ka wai i loko o ka smearing film dialysis mai ka kiʻiʻoniʻoni a neʻe i ka ʻauʻau e hoʻoheheʻe i ke kiʻiʻoniʻoni. ʻO kēia ka electroosmosis. Hoʻololi ʻo Electroosmosis i ke kiʻi ʻoniʻoni hydrophilic i kahi kiʻiʻoniʻoni hydrophobic coating, a ʻo ka dehydration ka mea e paʻa ai ke kiʻi uhi. Hiki ke hoʻopā ʻia ka pena pulu ma hope o ka ʻauʻau ʻana me ka pena electrophoretic electro-osmosis maikaʻi a ʻaʻole pili. Hiki iā ʻoe ke hoʻomaʻemaʻe i ka wai ʻauʻau e pili ana i ke kiʻi pena wai me ka wai.

Nā ʻano o ka Electrocoating

Loaʻa i ka kiʻi pena electrophoretic nā mea maikaʻi o ka piha, ka like ʻole, ka palahalaha a me ka uhi ʻoluʻolu. ʻOi aku ka maikaʻi o ka paʻakikī, adhesion, corrosion resistance, hopena hopena, a me ka permeability o ka kiʻi pena electrophoretic ma mua o nā kaʻina hana uhi ʻē aʻe.

(1) Hoʻohana ʻia ka pena wai-soluble, hoʻohana ʻia ka wai ma ke ʻano he mea hoʻoheheʻe, ka mea e mālama ai i ka nui o nā mea hoʻoheheʻe organik, hoʻemi nui i ka haumia o ka ea a me nā pōʻino o ke kaiapuni, palekana a maʻemaʻe, a pale i ka pilikia huna o ke ahi;

(2) He kiʻekiʻe ka maikaʻi o ka pena pena, liʻiliʻi ka poho o ka pena, a hiki i ka hoʻohana ʻana o ka pena ke hiki i 90% a 95%;

(3) Ua like ka mānoanoa o ke kiʻiʻoniʻoni, ikaika ka hoʻopili ʻana, a maikaʻi ka maikaʻi o ka uhi. Hiki i kēlā me kēia ʻāpana o ka mea hana, e like me ka papa o loko, nā puʻu, nā welds, a me nā mea ʻē aʻe, hiki ke loaʻa i kahi kiʻi ʻoniʻoni ʻoniʻoni a me ka maʻalahi, e hoʻonā i ka pilikia o nā ʻano hana hoʻopili ʻē aʻe no nā mea hana paʻakikī. Ka pilikia pena;

(4) He kiʻekiʻe ka maikaʻi o ka hana, a hiki i ke kūkulu ke hoʻomaopopo i ka hana maʻalahi a hoʻomau, e hoʻomaikaʻi nui i ka hana hana;

(5) He paʻakikī nā mea hana, he kiʻekiʻe ke kumukūʻai hoʻolimalima, nui ka hoʻohana ʻana i ka mana, kiʻekiʻe ka mahana e pono ai no ka hoʻomaloʻo ʻana a me ka hoʻōla ʻana, paʻakikī ka mālama ʻana i ka pena a me ka pena, paʻa nā kūlana kūkulu, a koi ʻia ka mālama ʻana i ka wai. ;

(6) Hiki ke hoʻohana wale i ka pena wai-soluble, a ʻaʻole hiki ke hoʻololi ʻia ke kala i ka wā o ka uhi ʻana. ʻAʻole maʻalahi ka paʻa o ka pena ma hope o ka mālama ʻana no ka manawa lōʻihi.

(7) He mea paʻakikī ka mea hoʻopili electrophoretic a he kiʻekiʻe ka ʻenehana, kahi kūpono no ka hana ʻana i ke kala paʻa.

Ka palena o ka Electrocoating

(1) He kūpono wale ia no ka uhi mua ʻana o nā substrates conductive e like me nā ʻāpana mīkini o nā metala ferrous a me nā metala non-ferrous. ʻAʻole hiki ke uhi ʻia nā mea hana ʻole e like me ka lāʻau, plastic, lole, etc.

(2) ʻAʻole kūpono ke kaʻina hana uhi electrophoresis no nā mea i uhi ʻia me nā metala he nui, inā ʻokoʻa nā ʻano electrophoresis.

(3) ʻAʻole hiki ke hoʻohana ʻia ke kaʻina hana hoʻopili electrophoretic no nā mea i uhi ʻia ʻaʻole hiki ke kū i ka wela kiʻekiʻe.

(4) ʻAʻole kūpono ka uhi electrophoretic no ka uhi ʻana me nā koi palena ʻole i ke kala. Pono e pena ʻia ka uhi electrophoretic o nā waihoʻoluʻu like ʻole.

(5) ʻAʻole ʻōlelo ʻia ka uhi electrophoretic no ka hana liʻiliʻi liʻiliʻi (ʻo ka manawa hou o ka ʻauʻau ʻoi aku ma mua o 6 mau mahina), no ka mea, ua lohi loa ka wikiwiki o ka ʻauʻau, ua ʻelemakule ka resin i ka ʻauʻau a ua loli ka ʻike. nui loa. Paʻa ka ʻauʻau.

Nā ʻanuʻu o ka Electrocoating

(1) No ka uhi electrophoretic o nā ʻili metala maʻamau, ʻo ke kaʻina hana: hoʻomaʻemaʻe mua → degreasing → holoi wai → wehe ʻana i ka wai → holoi wai → neutralization → holoi wai → phosphating → holoi wai → passivation → uhi electrophoretic → tank top Cleaning → ka holoi wai ultrafiltration → maloʻo → offline.

(2) He hopena nui ka substrate a me ka pretreatment o ka mea i uhi ʻia i ke kiʻi ʻoniʻoni electrophoretic coating. Hoʻopau pinepine ʻia nā mea hoʻolei metala e ka sandblasting a i ʻole ka pana ʻana i ka pana, hoʻohana ʻia ka lole pulupulu no ka wehe ʻana i ka lepo lana ma luna o ka ʻili o ka mea hana, a hoʻohana ʻia ka sandpaper e wehe i ke koena o nā pana kila a me nā ʻōpala ʻē aʻe ma luna o ka ʻili. Hoʻopili ʻia ka ʻili kila me ka degreasing a me ka wehe ʻana i ka ʻōpala. Ke kiʻekiʻe loa nā koi o ka ʻili, pono ka phosphating a me ka passivation surface treatments. Pono e phosphated nā mea hana metala ferrous ma mua o ka electrophoresis anodic, inā ʻaʻole e ʻilihune ka pale ʻana i ka corrosion o ke kiʻi pena. I ka phosphating lapaʻau, zinc paʻakai phosphating kiʻiʻoniʻoni koho maʻamau, me ka mānoanoa o ma kahi o 1 a 2 μm, a me ka phosphate kiʻiʻoniʻoni e loaʻa i ka maikai a me ka like like kristal.

(3) I ka ʻōnaehana kānana, hoʻohana maʻamau ka kānana mua, a ʻo ka kānana he ʻeke ʻeke mesh. Lawe ʻia ka peʻa electrophoretic i ka kānana ma o ka paila kū i luna no ka kānana. Ke noʻonoʻo nei i ka pōʻai hoʻololi piha a me ka maikaʻi o ke kiʻi pena, ʻo ka ʻeke kānana me ka nui pore o 50μm ka mea maikaʻi loa. ʻAʻole hiki iā ia ke hoʻokō wale i nā koi maikaʻi o ke kiʻi pena, akā hoʻoponopono pū i ka pilikia o ka ʻeke kānana clogging.

(4) ʻO ka nui o ka ʻōnaehana holo o ka electrophoretic coating e pili pono i ka paʻa o ka ʻauʻau a me ka maikaʻi o ke kiʻi pena. ʻO ka hoʻonui ʻana i ka nui o ke kahe e hoʻemi i ka ua a me nā ʻōhū o ka wai ʻauʻau; akā naʻe, wikiwiki ka ʻelemakule o ka wai ʻauʻau, piʻi ka hoʻohana ʻana i ka ikehu, a ʻoi aku ka maikaʻi o ka paʻa o ka wai ʻauʻau. He mea kūpono ia e hoʻomalu i nā manawa pōʻai o ka wai pahu i 6-8 mau manawa / h, ʻaʻole ia e hōʻoiaʻiʻo wale i ka maikaʻi o ka kiʻi pena, akā e hōʻoiaʻiʻo i ka hana paʻa o ka wai pahu.

(5) Ke piʻi aʻe ka manawa hana, e hoʻonui ka impedance o ka diaphragm anode a e emi iho ka volta hana pono. No laila, i ka hana ʻana, pono e hoʻonui lohi ʻia ka volta hana o ka mana e like me ka nalowale o ka volta e uku ai i ka hāʻule o ka volta o ka diaphragm anode.

(6) Mālama ka ʻōnaehana ultrafiltration i ka ʻike o nā ion haumia i lawe ʻia e ka mea hana e hōʻoia i ka maikaʻi o ka uhi. I ka hana ʻana o kēia ʻōnaehana, pono e hoʻomaopopo ʻia i ka wā e hana ai ka ʻōnaehana, pono e holo mau a pāpā ʻia ʻo ia e holo ma waena o ka pale ʻana i ka membrane ultrafiltration mai ka maloʻo ʻana. Hoʻopili ka resin maloʻo a me ka puaʻa i ka membrane ultrafiltration a ʻaʻole hiki ke hoʻomaʻemaʻe maikaʻi ʻia, e hoʻopilikia nui i ka wai permeability a me ke ola lawelawe o ka membrane ultrafiltration. Hōʻike ka nui o ka wai o ka membrane ultrafiltration i kahi hiʻohiʻona i lalo me ka manawa holo. Pono e hoʻomaʻemaʻe hoʻokahi no 30-40 mau lā o ka hana mau e hōʻoia i ka wai ultrafiltration e pono ai no ka ultrafiltration leaching a me ka holoi ʻana.

(7) He kūpono ke ʻano hana hoʻopili electrophoretic no ke kaʻina hana o ka nui o nā laina hui. Pono ka pōʻai hou o ka ʻauʻau electrophoresis i loko o 3 mau mahina. He mea koʻikoʻi ka hoʻokele ʻepekema o ka ʻauʻau. Hoʻāʻo mau ʻia nā ʻāpana like ʻole o ka ʻauʻau, a hoʻoponopono ʻia ka ʻauʻau a hoʻololi ʻia e like me nā hopena hōʻike. ʻO ka mea maʻamau, ua ana ʻia nā palena o ka wai ʻauʻau ma ke alapine aʻe: ka waiwai pH, ka ʻike paʻa a me ka conductivity o ka solution electrophoresis, ka hopena ultrafiltration a me ka hoʻomaʻemaʻe ultrafiltration solution, anion (anode) polar solution, circulating lotion, a me ka hoʻomaʻemaʻe deionization i hoʻokahi manawa. he lā; ʻO ka ratio kumu, ka mea hoʻoheheʻe kūlohelohe, a me ka hoʻāʻo ʻana i ka pahu liʻiliʻi hale hana ʻelua i ka pule.

(8) No ka mālama ʻana i ka maikaʻi o ke kiʻi pena, pono e nānā pinepine ʻia ka like ʻole a me ka mānoanoa o ka kiʻi pena, a ʻaʻole pono nā pinholes, sagging, peel alani, wrinkles, etc. E nānā mau i ke kino a me ke kemika. nā hōʻailona e like me ka adhesion a me ka corrosion resistance o ke kiʻi uhi. ʻO ka pōʻaiapuni nānā e like me nā kūlana nānā o ka mea hana, a maʻamau pono e nānā ʻia kēlā me kēia pūʻulu.

Lapaʻau ʻili ma mua o ka Electrophoresis

ʻO ka hoʻomaʻamaʻa ʻana i ka ʻili o ka mea hana ma mua o ka uhi ʻana he ʻāpana koʻikoʻi o ka uhi electrophoretic, ka mea nui e pili ana i ka degreasing, ka hoʻohemo ʻana i ka ʻōpala, ka hoʻomaʻamaʻa ʻana, ka phosphating a me nā kaʻina hana ʻē aʻe. ʻAʻole pili ka maikaʻi o kāna mālama ʻana i ke ʻano o ke kiʻiʻoniʻoni, e hōʻemi ana i ka hana anti-corrosion, akā e hoʻopau pū i ka paʻa o ka hopena pena. No laila, no ka ʻili o ka mea hana ma mua o ka pena ʻana, pono ia e kaʻawale i nā ʻili aila, nā ʻōpala, ʻaʻohe mea hoʻomaʻamaʻa mua a me ka sedimentation phosphating, a me nā mea ʻē aʻe. E pili ana i nā kaʻina hana mua o ka mālama ʻana, ʻaʻole mākou e kamaʻilio pākahi iā lākou, akā hāʻawi wale i kekahi mau manaʻo:

1) Inā ʻaʻole maʻemaʻe ka degreasing a me ka ʻōpala, ʻaʻole ia e pili wale i ka hoʻokumu ʻana o ke kiʻi phosphating, akā pili pū nō hoʻi i ka ikaika hoʻopaʻa, ka hana hoʻonaninani a me ke kūpaʻa corrosion o ka uhi. ʻO ke kiʻi pena e maʻalahi i ka emi a me nā pinhole.

2) Phosphating: ʻO ke kumu ka hoʻomaikaʻi ʻana i ka hiki ke hoʻopili a me ka anti-corrosion o ke kiʻi electrophoretic. Penei kona kuleana:

(1) Ma muli o nā hopena kino a me nā kemika, hoʻonui ʻia ka hoʻopili ʻana o ke kiʻi ʻoniʻoni organik i ka substrate.

(2) Hoʻohuli ke kiʻi phosphating i ka ʻili metala mai kahi alakaʻi maikaʻi i kahi alakaʻi maikaʻi ʻole, a laila e kāohi ai i ka hoʻokumu ʻia ʻana o nā micro-batteries ma ka ʻili metala, e pale pono ai i ka corrosion o ka uhi, a me ka hoʻonui ʻana i ke kūpaʻa corrosion a me ka pale wai o ka. ka uhi ʻana. Eia kekahi, ma ke kumu wale nō o ka hoʻohaʻahaʻa ʻana a me ka degreasing, hiki ke hana ʻia kahi kiʻiʻoniʻoni phosphating maikaʻi ma luna o kahi maʻemaʻe, ʻaʻahu, a me ka momona ʻole. Mai kēia hiʻohiʻona, ʻo ke kiʻiʻoniʻoni phosphating ponoʻī ka mea ʻoi loa ka intuitive a hilinaʻi ponoʻī i ka hopena o ke kaʻina hana pretreatment.

3) Holoi: ʻO ka maikaʻi o ka holoi ʻana i kēlā me kēia manawa o ka hoʻomaʻamaʻa mua ʻana e loaʻa i ka hopena nui i ka maikaʻi o ka hoʻomaʻamaʻa holoʻokoʻa a me ke kiʻi pena. ʻO ka hoʻomaʻemaʻe wai deionized hope loa ma mua o ka pena ʻana, e hōʻoia ʻaʻole ʻoi aku ka nui o ka conductivity dripping o ka mea i uhi ʻia ma mua o 30μs/cm. ʻAʻole maʻemaʻe ka hoʻomaʻemaʻe, e like me ka mea hana:

(1) Ke koena waika, phosphating chemical wai, flocculation o ka resin i loko o ka wai pena, a me ka deterioration o ka paʻa;

(2) ʻO nā mea ʻē aʻe (nā ʻaila hinu, ka lepo), nā lua shrinkage, nā ʻāpana a me nā hemahema ʻē aʻe i loko o ke kiʻi pena;

(3) ʻO ke koena electrolytes a me nā paʻakai ke alakaʻi i ka hoʻonui ʻana i ka hopena electrolysis a hana i nā pinholes a me nā maʻi ʻē aʻe.

Ka manawa hoʻouna: Apr-17-2021