Ka hao hina hinanā huahana hoʻoheheʻe ʻia ʻana o ka pūpūme na lawelawe oʻO ka mīkini CNC, lapaʻau wela a mālama ʻili.

ʻO ka hao hina, a i ʻole ka hao hina hina, he ʻano hao hao i loaʻa kahi microstructure graphite. Kapa ʻia ʻo ia ma muli o ke kala hina o ka haʻihaʻi i hana ʻia. Hoʻohana ʻia ka hao hina hina no nā hale kahi i ʻoi aku ka nui o ka ʻoʻoleʻa o ka ʻāpana ma mua o kona ikaika tensile, e like me nā poloka cylinder engine combustion i loko, nā hale pahū, nā kino valve, nā pahu uila, nā paona kūʻē a me nā mea hoʻonaninani. Hoʻohana pinepine ʻia ka haʻahaʻa haʻahaʻa haʻahaʻa o ka hao hao hina a me ke poʻo kikoʻī e hana i nā mea kuke hao hao a me nā rotors brake disc.

ʻO kahi haku mele maʻamau no ka loaʻa ʻana o kahi microstructure graphitic he 2.5 a 4.0% kalapona a me 1 a 3% silika ma ke kaupaona. Hiki i ka graphite ke noho ma 6 a 10% o ka nui o ka hao hina. He mea koʻikoʻi ka silikoni i ka hana ʻana i ka hao hina e like me ka hao hao keʻokeʻo, no ka mea, ʻo ka silicon kahi mea hoʻopaʻa graphite i loko o ka hao, ʻo ia hoʻi ke kōkua i ka hana ʻana i ka graphite ma kahi o ka hao carbide; ma 3% silika aneane ʻaʻohe kalapona i hoʻopaʻa ʻia i ka hui kemika me ka hao.

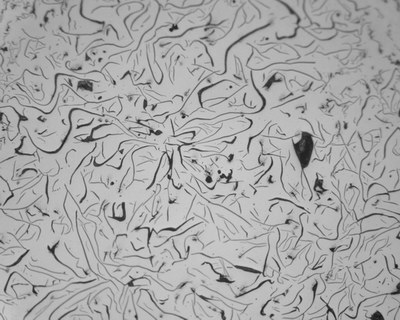

Lawe ka graphite i ke ʻano o kahi flake ʻekolu. Ma nā ʻāpana ʻelua, ʻoiai e ʻike ʻia kahi ʻili i poni ʻia ma lalo o kahi microscope, ʻike ʻia nā flakes graphite e like me nā laina maikaʻi. ʻO nā ʻaoʻao o nā lau e like me nā notches mua; no laila, he palupalu. ʻO ka loaʻa ʻana o nā graphite flakes e maʻalahi ai ka Grey Iron me ka maʻalahi o ka poʻe maʻalahi ma nā ʻāpana graphite. ʻO ka hao hina maikaʻi hoʻi ka hiki ke hoʻoheheʻe maikaʻi ʻia a no laila ua hoʻohana nui ʻia ʻo ia ke kumu no nā kau ʻana o ka mīkini.

Na Mea Mekanika o ka Hao Hoolei Hina | |||||||

| Mea e like me DIN EN 1561 | Ana | Unite | EN-GJL-150 | EN-GJL-200 | EN-GJL-250 | EN-GJL-300 | EN-GJL-350 |

| EN-JL 1020 | EN-JL 1030 | EN-JL 1040 | EN-JL 1050 | EN-JL 1060 | |||

| Ikaika U'i | Rm | MPA | 150-250 | 200-300 | 250-350 | 300-400 | 350-450 |

| 0.1% Ka ikaika hua | Rp0,1 | MPA | 98-165 | 130-195 | 165-228 | 195-260 | 228-285 |

| Ka ikaika elongation | A | % | 0,3 – 0,8 | 0,3 – 0,8 | 0,3 – 0,8 | 0,3 – 0,8 | 0,3 – 0,8 |

| Ka ikaika hoʻopili | σdB | MPa | 600 | 720 | 840 | 960 | 1080 |

| 0,1% Ka ikaika hoʻopili | σd0,1 | MPa | 195 | 260 | 325 | 390 | 455 |

| Ikaika Flexural | σbB | MPa | 250 | 290 | 340 | 390 | 490 |

| Schuifspanning | σaB | MPa | 170 | 230 | 290 | 345 | 400 |

| ʻOkoʻolua Shear | TtB | MPa | 170 | 230 | 290 | 345 | 400 |

| Nā modula o ka elasticity | E | GPa | 78 – 103 | 88 – 113 | 103 – 118 | 108 – 137 | 123 – 143 |

| Helu Poisson | v | – | 0,26 | 0,26 | 0,26 | 0,26 | 0,26 |

| ʻO Brinell paʻakikī | HB | 160 – 190 | 180 – 220 | 190 – 230 | 200 – 240 | 210 – 250 | |

| ʻO ka ductility | σbW | MPa | 70 | 90 | 120 | 140 | 145 |

| Hoʻololi ka hoʻopaʻapaʻa a me ke kaomi | σzdW | MPa | 40 | 50 | 60 | 75 | 85 |

| Ikaika Haʻihaʻi | Klc | N/mm3/2 | 320 | 400 | 480 | 560 | 650 |

| ʻO ka mānoanoa | g/cm3 | 7,10 | 7,15 | 7,20 | 7,25 | 7,30 | |

Ka hoʻoheheʻe ʻia ʻana o ka pūpūUa kapa ʻia ke kaʻina hana hoʻoheheʻe ʻana i ke one resin pre-coated, nā hoʻoheheʻe ʻana i ka pūpū wela a i ʻole ke kaʻina hoʻolei kumu. ʻO ka mea hoʻoheheʻe nui ka one phenolic resin pre-coated, ʻoi aku ka maikaʻi ma mua o ke one ʻōmaʻomaʻo a me ke one furan resin. Eia kekahi, ʻaʻole hiki ke hoʻohana hou ʻia kēia one.

ʻO ke kaʻina hoʻolei one paʻakikī paʻakikī Furan resin (nobake process) hoʻohana i ke one i uhi ʻia i ka furan resin e hana i ka mold. Ma hope o ka hui ʻana i ke one kumu (a i ʻole ke one i hoʻihoʻi ʻia), ka wai furan resin a me ka catalyst wai me ka like, a hoʻopiha iā lākou i loko o ka pahu kumu (a i ʻole pahu one), a laila e hoʻopaʻa i ka paʻakikī i loko o kahi ʻōpala a i ʻole i loko o ka pahu kumu (a i ʻole ke one. pahu) ma ka lumi wela. A laila ua hoʻokumu ʻia ka pahu hoʻoheheʻe a i ʻole ka hoʻoheheʻe ʻana i ke kumu, i kapa ʻia ʻo ia hoʻi ka paʻakikī paʻakikī paʻakikī pahu pahu (core), a i ʻole ke ʻano hana paʻakikī (core).

No ka mea, ua hoʻokumu ʻia ka mold i ka lumi wela a ʻaʻole pono e wela, ua kapa ʻia ka hoʻolei ʻana i ke one paʻakikī ponoʻī. Hiki ke hoʻokaʻawale ʻia ke ʻano paʻakikī paʻakikī i loko o ka acid-catalyzed furan resin a me ka phenolic resin sand self-hardening method, urethane resin sand self-hardening method and phenolic monoester self-hardening method.

Ma ke ʻano he one hoʻopaʻa pahu pahu anu paʻakikī ponoʻī, ʻo ke one furan resin ka mea mua loa a i kēia manawa i hoʻohana nui ʻia i ke one synthetic binder i loko o ka hale kūkulu Kina. ʻO ka nui o ka resin i hoʻohui ʻia i ke one hoʻoheheʻe ʻia ma ke ʻano he 0.7% a 1.0%, a ʻo ka nui o ka resin i hoʻohui ʻia i ke one kumu maʻamau he 0.9% a 1.1%. ʻO ka maʻiʻo o ka aldehyde manuahi i ka resin furan aia ma lalo o 0.3%, a ua hāʻule kekahi mau hale hana ma lalo o 0.1%. I loko o nā hale kūʻai ma Kina, ua hōʻea ke one paʻakikī paʻakikī furan resin i ka pae honua me ka nānā ʻole i ke kaʻina hana a me ka maikaʻi o ka ʻili o nā castings.

Papa Kaulike o ka hao hina hina | ||||||||

| AISI | W-paʻa | DIN | BS | SS | AFNOR | UNE / IHA | JIS | UNI |

| A48-20B | 0.6010 | GG-10 | Papa 100 | 0110-00 | - | - | FC 100 | G 10 |

| A48-25B | 0.6015 | GG-15 | Papa 150 | 0115-00 | Ft 15 D | FG 15 | FC 150 | G 15 |

| A48-30B | 0.6020 | GG-20 | Papa 200 | 0120-00 | Ft 20 D | FG 20 | FC 200 | G 20 |

| A48-40B | 0.6025 | GG-25 | Papa 250 | 0125-00 | Ft 25 D | FG 25 | FC 250 | G 25 |

| A48-45B | 0.6030 | GG-30 | Papa 300 | 0130-00 | Ft 30 D | FG 30 | FC 300 | G 30 |

| A48-50B | 0.6035 | GG-35 | Papa 350 | 0135-00 | Ft 35 D | FG 35 | FC 350 | G 35 |

| A48-60B | 0.6040 | GG-40 | Papa 400 | 0140-00 | Ft 40 D | - | FC 40 | - |

| 32510 | GTS-35 | B340/12 | 0815-00 | MN 35-10 | - | FCMW 330 | - | |

| A220-40010 | 0.8145 | GTS-45 | P440/7 | 0852-00 | MN 450 | - | FCMP 440/490 | GMN 45 |

| A220-50005 | 0.8155 | GTS-55-04 | P510/4 | 0854-00 | MP 50-5 | - | FCMP 490 | GMN 55 |

| A220-70003 | 0.8165 | GTS-65-02 | P570/3 | 0856-00 | MN 650-3 | - | FCMP 590 | GMN 65 |

| A220-70003 | - | GTS-65 | P570/3 | 0858 | MN 60-3 | - | FCMP 540 | - |

| A220-80002 | 0.8170 | GTS-70-02 | P690/2 | 0862-00 | MN 700-2 | - | FCMP 690 | GMN 70 |

ʻO ke one hoʻoheheʻe resina me nā mea hoʻohui | |

| Metala & Alloys | Papa kaulana |

| Hao Hao Hina | GG10~GG40; GJL-100 ~ GJL-350; |

| Ka hao hoolei (Nodular). | GGG40 ~ GGG80; GJS-400-18, GJS-40-15, GJS-450-10, GJS-500-7, GJS-600-3, GJS-700-2, GJS-800-2 |

| Austempered Ductile Iron (ADI) | EN-GJS-800-8, EN-GJS-1000-5, EN-GJS-1200-2 |

| ʻO ka hao hao | C20, C25, C30, C45 |

| ʻAiʻa kila | 20Mn, 45Mn, ZG20Cr, 40Cr, 20Mn5, 16CrMo4, 42CrMo, 40CrV, 20CrNiMo, GCr15, 9Mn2V |

| Kila kohu ʻole | ʻIle ʻoleʻa Ferritic, ʻIle Kūleʻa ʻole Martensitic, ʻIle Kūleʻa Austenitic, ʻIle Kūleʻa Paʻa ka ua |

| Aluminum Alloys | ASTM A356, ASTM A413, ASTM A360 |

| Ke keleawe / Copper-based Alloys | C21000, C23000, C27000, C34500, C37710, C86500, C87600, C87400, C87800, C52100, C51100 |

| Kūlana: ASTM, SAE, AISI, GOST, DIN, EN, ISO, a me GB | |

ʻO nā pono o ka Furan Resin Coated Sand Self-hardening Molding Casting:

1) E hoʻomaikaʻi i ka pololei o ka nui o nā castings a me ka ʻili o ka ʻili.

2) ʻAʻole pono ka hoʻomaloʻo ʻana o ke one (core) paʻakikī, hiki ke hoʻopakele i ka ikehu, a hiki ke hoʻohana ʻia nā pahu lāʻau a i ʻole nā pahu a me nā mamana.

3) He mea maʻalahi ka hoʻopili ʻana a me ka hāʻule ʻana o ke one paʻakikī ponoʻī, maʻalahi e hoʻomaʻemaʻe i ka hoʻolei ʻana, a hiki ke hoʻohana hou ʻia ke one kahiko, kahi e hoʻemi nui ai i ka ikaika o ka hana ʻana, hoʻohālike, hāʻule ke one, hoʻomaʻemaʻe a me nā loulou ʻē aʻe, a maʻalahi ka hoʻomaopopo ʻana i ka mechanization a i ʻole automation.

4) ʻO ka hapa nui o ka resin ma ke one he 0.8% ~ 2.0% wale nō, a he haʻahaʻa ke kumukūʻai piha o nā mea maka.

No ka mea he nui nā pono kū hoʻokahi i ʻōlelo ʻia ma luna, ʻaʻole hoʻohana ʻia ke ʻano paʻakikī ponoʻī no ka hana kumu, akā hoʻohana ʻia no ka hoʻoheheʻe ʻana. He mea kūpono ia no ka ʻāpana hoʻokahi a me ka hana liʻiliʻi liʻiliʻi, a hiki ke hana i ka hao hao, ke kila a me ka hoʻoheheʻe ʻole ʻia. Ua hoʻololi loa kekahi mau hale kūʻai ʻo Kina i nā lepo lepo maloʻo, nā lepo lepo sima, a me nā ʻāpana one aniani wai.

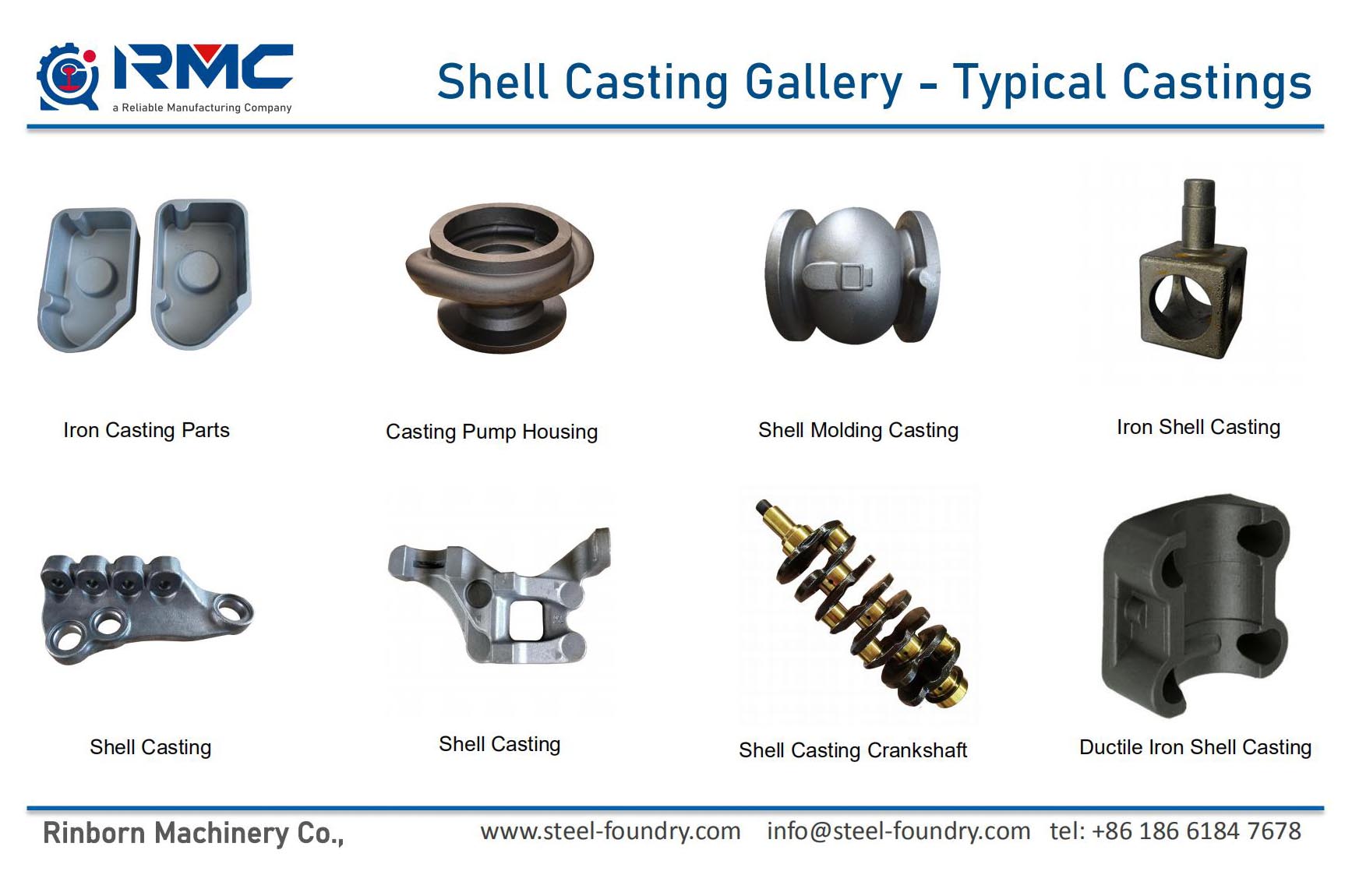

Nā huahana hoolei hao maʻamau