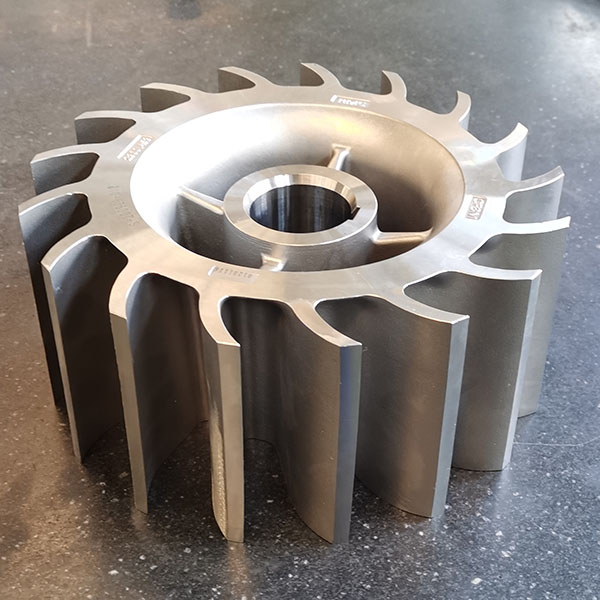

ʻO OEM duplex maʻamau 2205/1.4462 hoʻolele kila kila me nā lawelawe machining CNC mai Kinahoʻoheheʻe kālā.

Duplex 2205 hoolei kila kilaʻo ia hoʻi nā hoʻolei ʻana i hana ʻia me ka duplex stainless steel. ʻO ka Duplex Stainless Steel (DSS) e pili ana i ke kila kila me ka ferrite a me ka austenite i kēlā me kēia helu no kahi o 50%. ʻO ka maʻamau, ʻo ka maʻiʻo o nā ʻāpana liʻiliʻi e pono ma kahi o 30%. I ka hihia o ka haʻahaʻa C maʻiʻo, ka Cr maʻiʻo ka 18% a 28%, a me ka Ni maʻiʻo mea 3% a 10%. Loaʻa i kekahi mau mea kila kila duplex e like me Mo, Cu, Nb, Ti, a me N.

Loaʻa i ka DSS nā hiʻohiʻona o ka austenitic a me ka ferritic stainless steel. Hoʻohālikelike ʻia me ka ferrite, ʻoi aku ka kiʻekiʻe o ka plasticity a me ka ductility, ʻaʻohe lumi wela brittleness, a me ka hoʻomaikaʻi maikaʻi ʻana i ke kūpaʻa intergranular corrosion a me ka hana kuʻi, ʻoiai e mālama mau ana i ka brittleness, kiʻekiʻe thermal conductivity, a super plasticity e like me ka ferrite stainless steel. Ke hoʻohālikelike ʻia me ka austenitic stainless steel, he ikaika kiʻekiʻe ka DSS a hoʻomaikaʻi maikaʻi i ke kūʻē ʻana i ka corrosion intergranular a me ka corrosion stress chloride.Duplex kila kilamaikaʻi loa ka pale ʻana i ka corrosion pitting a ʻo ia hoʻi he kila kila hoʻopakele nickel.

| Na lako noKaʻina hoʻolei kālāma RMC

| |||

| Māhele | Papa Kina | Papa US | Kelemānia Papa |

| ʻO Ferritic Stainless Steel | 1Cr17, 022Cr12, 10Cr17, | 430, 431, 446, CA-15, CA6N, CA6NM | 1.4000, 1.4005, 1.4008, 1.4016, GX22CrNi17, GX4CrNi13-4 |

| He kila kila ʻole Martensitic | 1Cr13, 2Cr13, 3Cr13, 4Cr13, | 410, 420, 430, 440B, 440C | 1.4021, 1.4027, 1.4028, 1.4057, 1.4059, 1.4104, 1.4112, 1.4116, 1.4120, 1.4122, 1.4125 |

| Austenitic kila kila | 06Cr19Ni10, 022Cr19Ni10, 06Cr25Ni20, 022Cr17Ni12Mo2, 03Cr18Ni16Mo5 | 302, 303, 304, 304L, 316, 316L, 329, CF3, CF3M, CF8, CF8M, CN7M, CN3MN | 1.3960, 1.4301, 1.4305, 1.4306, 1.4308, 1.4313, 1.4321, 1.4401, 1.4403, 1.4404, 1.4405, 1.4404, 4,1,4404 1.4435, 1.4436, 1.4539, 1.4550, 1.4552, 1.4581, 1.4582, 1.4584, |

| Pilikia Paʻa Paʻa Ua | 05Cr15Ni5Cu4Nb, 05Cr17Ni4Cu4Nb | 630, 634, 17-4PH, 15-5PH, CB7Cu-1 | 1.4542 |

| Duplex Steel Steel | 022Cr22Ni5Mo3N, 022Cr25Ni6Mo2N | A 890 1C, A 890 1A, A 890 3A, A 890 4A, A 890 5A, A 995 1B, A 995 4A, A 995 5A, 2205, 2507 | 1.4460, 1.4462, 1.4468, 1.4469, 1.4517, 1.4770 |

| Kiekie Mn Steel | ZGMn13-1, ZGMn13-3, ZGMn13-5 | B2, B3, B4 | 1.3802, 1.3966, 1.3301, 1.3302 |

| Mea hao hao | Cr12 | A5, H12, S5 | 1.2344, 1.3343, 1.4528, GXCrMo17, X210Cr13, GX162CrMoV12 |

| Ke kila pale wela | 20Cr25Ni20, 16Cr23Ni13, 45Cr14Ni14W2Mo | 309, 310, CK20, CH20, HK30 | 1.4826, 1.4828, 1.4855, 1.4865 |

| Alloy kumu nikela | HASTELLY-C, HASTELLY-X, SUPPER22H, CW-2M, CW-6M, CW-12MW, CX-2MW, HX(66Ni-17Cr), MRE-2, NA-22H, NW-22, M30C, M-35 -1, INCOLOY600, INCOLOY625 | 2.4815, 2.4879, 2.4680 | |

| Aluminum Alloy | ZL101, ZL102, ZL104 | ASTM A356, ASTM A413, ASTM A360 | G-AlSi7Mg, G-Al12 |

| Aloe keleawe | H96, H85, H65, HPb63-3, HPb59-1, QSn6.5-0.1, QSn7-0.2 | C21000, C23000, C27000, C34500, C37710, C86500, C87600, C87400, C87800, C52100, C51100 | CuZn5, CuZn15, CuZn35, CuZn36Pb3, CuZn40Pb2, CuSn10P1, CuSn5ZnPb, CuSn5Zn5Pb5 |

| Alloy kumu-kobalt | UMC50, 670, Papa 31 | 2.4778 | |