ʻO ka Cobalt e pili ana i nā huahana hoʻoheheʻe ʻana i nā huahana mai Kina kumu mua me ka mālama wela a me nā lawelawe machining CNC

| Metala noKaʻina hoʻolei kālāma RMC | |||

| Māhele | Papa Kina | Papa US | Kelemānia Papa |

| ʻO ka hao hao | ZG15, ZG20, ZG25, ZG35, ZG45, ZG55, Q235, Q345, Q420 | 1008, 1015, 1018, 1020, 1025, 1030, 1035, 1040, 1045, 1050, 1060, 1070, WC6, WCC, WCB, WCA, LCB | 1.0570, 1.0558, 1.1191, 1.0619, 1.0446, GS38, GS45, GS52, GS60, 1.0601, C20, C25, C30, C45 |

| Haʻahaʻa Alloy Steel | 20Mn, 45Mn, ZG20Cr, 40Cr, 20Mn5, 16CrMo4, 42CrMo, 40CrV, 20CrNiMo, GCr15, 9Mn2V | 1117, 4130, 4140, 4340, 6150, 5140, WC6, LCB, Gr.13Q, 8620, 8625, 8630, 8640, H13 | GS20Mn5, GS15CrNi6, GS16MnCr5, GS25CrMo4V, GS42CrMo4, S50CrV4, 34CrNiMo6, 50CrMo4, G-X35CrMo17, 1.1131, 1.0037, 1.0122, 1.2162, 1.2542, 1.6511, 1.6523, 1.6580, 1.6580, 1.1.713 1.7225, 1.7227, 1.7228, 1.7231, 1.7321, 1.8519, ST37, ST52 |

| Kiekie Mn Steel | ZGMn13-1, ZGMn13-3, ZGMn13-5 | B2, B3, B4 | 1.3802, 1.3966, 1.3301, 1.3302 |

| Mea hao hao | Cr12 | A5, H12, S5 | 1.2344, 1.3343, 1.4528, GXCrMo17, X210Cr13, GX162CrMoV12 |

| Ke kila pale wela | 20Cr25Ni20, 16Cr23Ni13, 45Cr14Ni14W2Mo | 309, 310, CK20, CH20, HK30 | 1.4826, 1.4828, 1.4855, 1.4865 |

| Alloy kumu nikela | HASTELLY-C, HASTELLY-X, SUPPER22H, CW-2M, CW-6M, CW-12MW, CX-2MW, HX(66Ni-17Cr), MRE-2, NA-22H, NW-22, M30C, M-35 -1, INCOLOY600, INCOLOY625 | 2.4815, 2.4879, 2.4680 | |

| Alloy kumu-kobalt | UMC50, 670, Papa 31 | 2.4778 | |

ʻO ka pāpaʻi koʻikoʻi i hoʻokumu ʻia i ka Cobalt he mea paʻa paʻa e hiki ke kū i nā ʻano ʻano like ʻole o ka ʻaʻahu, corrosion a me ka wela wela. Hoʻokumu ʻia nā ʻāpana kobalt ma luna o ka cobalt e like me ka mea nui, i loaʻa ka nui o ka nickel, alloying chemical elements e like me chromium, tungsten a me kahi liʻiliʻi o nā mea hoʻohui e like me molybdenum, niobium, tantalum, titanium, lanthanum, a i kekahi manawa hao. . E like me ka ʻokoʻa o ka hui ʻana, hiki ke hoʻohana ʻia ka cobalt-based alloy i ke kaula kuʻi, a hiki ke hoʻohana ʻia ka pauka no ka hoʻoheheʻe ʻana i ka ʻili paʻakikī, ka hoʻoulu ʻana i ka wela, ka hoʻoheheʻe ʻana a me nā kaʻina hana ʻē aʻe, a hiki ke hana ʻia i nā hoʻoheheʻe. , forgings a me nā ʻāpana metallurgy pauda. Hoʻokaʻawale ʻia e ka hoʻohana hope ʻana, hiki ke hoʻokaʻawale ʻia nā mea hoʻoheheʻe ʻia i ka cobalt i loko o nā ʻāpana ʻaʻahu kūʻokoʻa i hoʻokumu ʻia i ka cobalt. Ma nā kūlana hana maʻamau, ʻaʻole lākou i ʻaʻahu a me ka wela kiʻekiʻe a i ʻole nā pale a me nā corrosion. Pono paha kekahi mau hana hana i ka wela kiʻekiʻe, ka ʻaʻahu a me ka pale ʻana i ka corrosion i ka manawa like. ʻOi aku ka paʻakikī o nā kūlana hana, ʻoi aku ka maikaʻi o nā pono o nā alloys-based cobalt.

ʻO nā waiwai o nā Alloy Cobalt-Based

ʻO nā carbide nui i loko o nā superalloys pili i ka cobalt ʻo MC, M23C6 a me M6C. I loko o nā ʻāpana kobalt i hoʻolei ʻia, ua hoʻoheheʻe ʻia ka M23C6 ma waena o nā palena palaoa a me nā dendrites i ka wā hoʻomaha mālie. I kekahi mau alalai, hiki i ka M23C6 maikaʻi ke hana i kahi eutectic me ka matrix γ. ʻO nā ʻāpana carbide MC he nui loa e loaʻa i kahi hopena koʻikoʻi i nā dislocations, no laila ʻaʻole maopopo ka hopena hoʻoikaika i ka alloy, ʻoiai nā carbide i hoʻopuehu maikaʻi i ka hopena hoʻoikaika maikaʻi. Hiki i nā carbide ma ka palena o ka palaoa (ʻo M23C6 ka nui) ke pale i ka paheʻe o ka palena o ka palaoa, a laila e hoʻomaikaʻi ai i ka ikaika hoʻomanawanui. ʻO ka microstructure o ka cobalt-based superalloy HA-31 (X-40) he māhele hoʻoikaika hoʻopuehu (CoCrW)6 C-type carbide. ʻO nā ʻāpana topological kokoke i hoʻopili ʻia e ʻike ʻia i loko o kekahi mau ʻāpana kobalt, e like me ke ʻano sigma he mea pōʻino a hoʻoheheʻe i ka alloy.

ʻOi aku ka maikaʻi o ke kūpaʻa wela o nā carbide i loko o nā ʻāpana kobalt. Ke piʻi ka mahana, ʻoi aku ka lohi o ka ulu ʻana o ka hōʻiliʻili carbide ma mua o ka ulu ʻana o ka pae γ i ka nickel-based alloy, a ʻoi aku ka kiʻekiʻe o ka mahana o ka hoʻoheheʻe hou ʻana i ka matrix (a hiki i 1100 ° C) . No laila, i ka pi'i 'ana o ka mahana, ka ho'oha'aha'a 'ana i ka cobalt e emi mālie ana ka ikaika o ka huila. Loaʻa i nā kobalt-based alloys maikaʻi ke kūpaʻa wela. ʻO ke kumu i ʻoi aku ai ka maikaʻi o nā alloys pili i ka cobalt ma mua o nā nickel-based alloys ma kēia ʻano, ʻo ka helu heheʻe o ka cobalt sulfide (e like me Co-Co4S3 eutectic, 877 ℃) ʻoi aku ka kiʻekiʻe ma mua o ka nickel ( No ka laʻana, Ni-Ni3S2 eutectic (645°C) kiʻekiʻe, a ʻoi aku ka haʻahaʻa o ka diffusion o ka sulfur i loko o ka cobalt ma mua o ka nickel ʻOi aku ka nui o ka chromium ma mua o ka nickel-based alloys, hiki iā lākou ke hana i kahi papa pale o ka alkali metala sulfate (e like me ka Cr2O3 pale pale i hoʻopili ʻia e Na2SO4) ma ka ʻili o ka mea hoʻohui ʻOi aku ka haʻahaʻa loa o nā alloys ma mua o nā alloys nickel-based.

ʻOkoʻa mai nā superalloys ʻē aʻe, ʻaʻole i hoʻoikaika ʻia nā superalloys hoʻokumu ʻia i ka cobalt e kahi ʻāpana ua i kauoha ʻia i hoʻopaʻa paʻa ʻia i ka matrix, akā ua haku ʻia me kahi matrix austenite fcc i hoʻoikaika ʻia ka hopena paʻa a me kahi ʻāpana carbide i puʻunaue ʻia i loko o ka matrix. ʻO ka hoʻolei ʻana i nā superalloys pili i ka cobalt e hilinaʻi nui i ka hoʻoikaika carbide. Loaʻa i nā kristal kobalt maʻemaʻe kahi hale aniani hexagonal kokoke i hoʻopili ʻia (hcp) ma lalo o 417°C, e hoʻololi ana i fcc i nā wela kiʻekiʻe. I mea e pale aku ai i kēia hoʻololi ʻana i ka wā o ka hoʻohana ʻana i nā superalloys hoʻokumu ʻia i ka cobalt, ua hoʻohui ʻia nā mea hoʻoheheʻe kobalt a pau me ka nickel i mea e hoʻopaʻa ai i ka hale mai ka wela lumi a hiki i ka wela wela. He pilina koʻikoʻi-mehana ka haʻihaʻi haʻihaʻi ʻana o nā kobalt-based alloys, akā hōʻike i ke kūpaʻa ʻana o ka wela wela ma luna o 1000°C ma mua o nā wela kiʻekiʻe ʻē aʻe.

ʻO ka hoʻoulu ʻana i ka wela o nā Alloys-Cobalt

ʻO ka nui a me ka hāʻawi ʻana i nā ʻāpana carbide a me ka nui o ka palaoa i loko o nā ʻāpana kobalt e pili pono ana i ke kaʻina hoʻolei. I mea e hoʻokō ai i ka ikaika hoʻomanawanui a me nā waiwai luhi wela o nā ʻāpana hoʻoheheʻe ʻana i ka cobalt-based alloy casting, pono e hoʻomalu ʻia nā ʻāpana kaʻina hana. Pono nā ʻāpana Cobalt e mālama i ka wela, ka mea nui e kāohi i ka ua o ka carbide. No ka hoʻoheheʻe ʻia ʻana o ka cobalt, e hoʻokō mua i ka hoʻoponopono paʻa paʻa wela kiʻekiʻe, maʻamau ma kahi o 1150°C, no laila e hoʻoheheʻe ʻia nā carbides mua a pau, me kekahi MC-type carbide, i mea paʻa; a laila, lawe ʻia ka mālama ʻelemakule ma 870-980 ° C. E hoʻokahe hou i nā carbide.

Nā Papa Maʻamau o nā Alloys-Cobalt

ʻO nā māka maʻamau o nā ʻāpana wela kiʻekiʻe e pili ana i ka cobalt: 2.4778 (e like me DIN EN 10295) Hayness 188, Haynes 25 (L-605), Alloy S-816, UMCo-50, MP-159, FSX-414, X -40, Stellite 6B, Papa 31, a me nā mea ʻē aʻe, ʻo nā hōʻailona Kina: GH5188 (GH188), GH159, GH605, K640, DZ40M a pēlā aku.

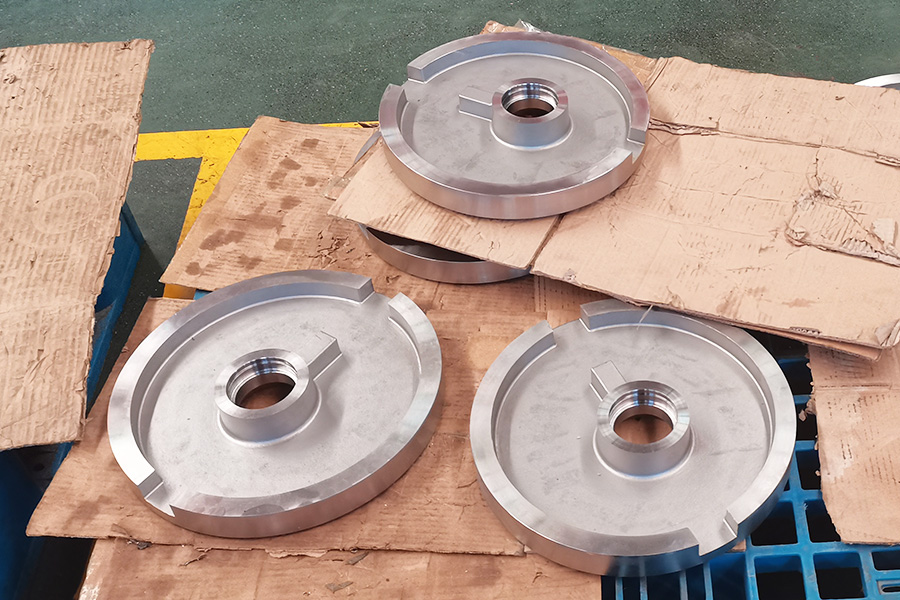

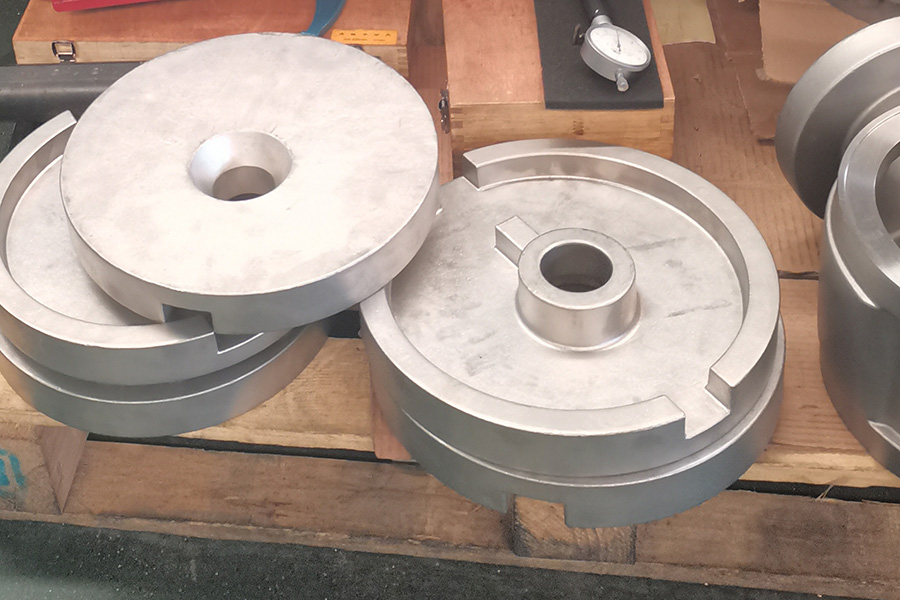

Noi o ka Cobalt-based Alloy Castings

ʻO ka maʻamau, nele nā superalloys i hoʻokumu ʻia i ka cobalt i nā hana hoʻoikaika koʻikoʻi. ʻOiai he haʻahaʻa ka ikaika ma ka mahana wela (ʻo 50-75% wale nō o nā alloys nickel-based), ʻoi aku ka ikaika o lākou, ke kūpaʻa luhi wela maikaʻi, ke kūpaʻa abrasion, ʻoi aku ka maikaʻi o ka weldability and thermal corrosion resistance ma luna o ka mahana o 980 ° C. No laila, ʻo ka hoʻoheheʻe ʻana o ka cobalt-based alloy he mea kūpono ia no ka hana ʻana i nā vanes alakaʻi a me nā nozzle guide vanes no nā ʻenekini mokulele mokulele, nā turbine kinoea ʻenehana, nā turbine kinoea moana, a me nā nozzles engine diesel, etc.